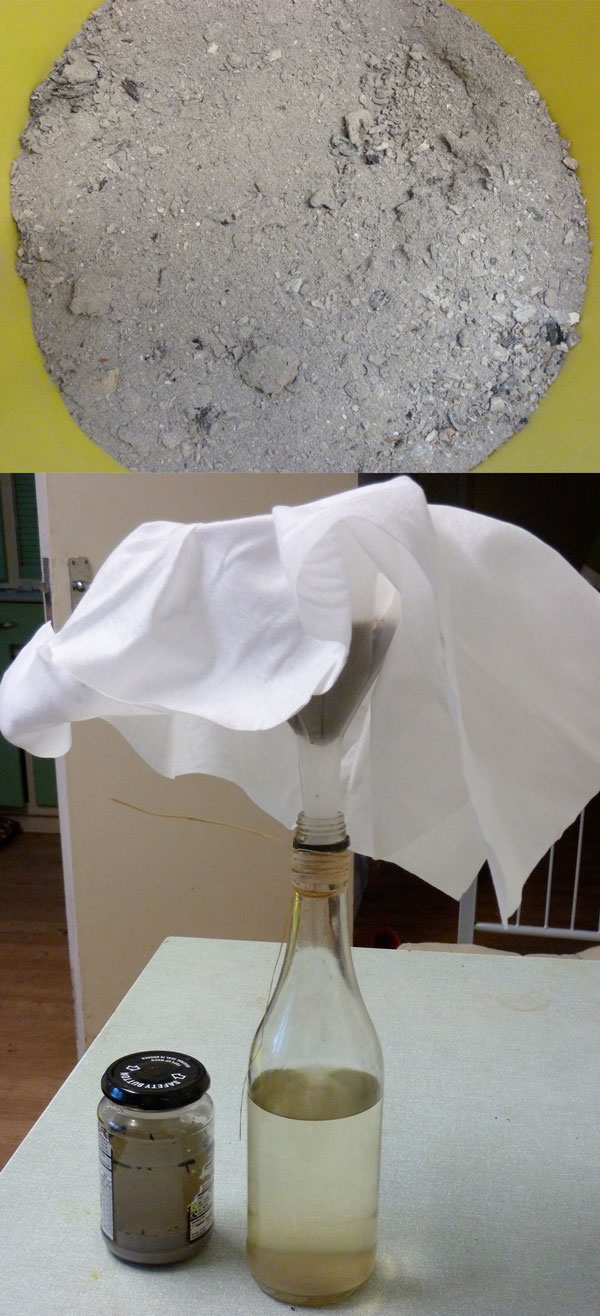

With the remaining wood liquor from my cooking, I wanted to test evaporating it off, the times it'll take and the residue left behind.

The liquid is reluctant to let much water evaporate away. The wood liquor with crushed charcoal left a very interesting goo. This test was done a month ago and the goo is still drying / hardening. I'll definitely keep an eye on it, as well as make a bigger sample to cook further.

The liquid is reluctant to let much water evaporate away. The wood liquor with crushed charcoal left a very interesting goo. This test was done a month ago and the goo is still drying / hardening. I'll definitely keep an eye on it, as well as make a bigger sample to cook further.

A Welsh recipe for Hemi-Cellulose

During my search for the sacred Lignin I was put in touch with the Bio Composites Centre, associated with Bangor University, North Wales. The lovely folks there were very kind to sit with me and discuss, in detail, my projects ambitions and set restrictions. I have limited my material palette to everything that surrounds me within Jan's Wood, with the addition of fuel for a chainsaw. Could organic chemistry provide all the key ingredients to make a mouldable material? I had been soaking and cooking wood in homemade Potash, created from wood ash - is this an adequate alkali to aid in the break down of my wood? Unfortunately they had to let me down gently. Lignin is a tough tough substance, separating it from the cellulose without strong chemicals like Sodium Hydroxide would be a tall order, or perhaps a miracle. OK - if I haven't been extracting Lignin during my cooking tests, what have I been left with?

Lignin is a complex and un-uniformed molecule structure with strong bonds. Within Lignin sits long but weaker glucose chains of Hemi-cellulose. When soaked and heated these sugars are the first bonds to be broken and released.

Bio Composite, Bangor gave me a recipe to test out an extraction of my own Hemi-cellulose, which I could use as a glaze, or perhaps a wood treatment....

As soon as the Potash (Potassium Carbonate K2CO3) was poured into the Willow shavings the colour change indictated that some reaction had happened, I much quicker reaction compared to soaking wood in water. The solution was boiled for 2 hours and the colour had become a wonderful deep red with an interesting fragrance. It was this liquor that I needed.

As the Potash, a fairly strong alkali, needed to be nuetralised, a standard acid was added until pH 7 was reached.

I was advised that an alcohol will react and condense together the sugars of the Hemi-cellulose, so Meths was trickled in until cloudy clumps formed.

Chemistry was never my strong subject, enjoyable, but baffling. Besides this being a complicated process, I was stabbing in the dark. Not being able to decipher exactly what I had created meant I had to abandon this clever chemistry and move on. Furthermore, this process involved large external ingredients with next to no yield of ... er... an opaque reddy/brown liquid that never seems to dry. Joy.

Charcoaling for Wood Vinegar

I'm on a quest to find a future for England's 649,000 hectares of unmanaged woodlands. Every year around 4 million tonnes of unharvested English timber is ignored, that equates to 800,000 tonnes of carbon store. To bring these forgotten plots of land back into management we could not only provide British industry with a vital raw material and fuel, but enhance and re-establish our declining wildlife, and ecology, something that can have a positive trickle effect on our agriculture.

My landlady's woodland, "Jan's wood", is my case study. What economical manufacturing process can I create within this 45 acre woodland, neglected but bursting with potential? So far I have been learning the intricate chemistry that lies within trees, and how this chemistry makes wood behave the way it does.

In particular, I have been referring to England's historical woodland based craft to understand how generations benefited from this material long before the Industrial Revolution.

Charcoal is created by heating any organic material (animal or plant) to temperatures up to 300 C in the absense of air. It is essentially carbon, the atomic building block within everything on this planet.

However, it was not charcoal that I was in hoping to collect. The heat creates a chemical decomposition of the wood, releasing a whole pick'n'mix of chemical goodies in the smoke - Pyroligneous Acid. Traditionally the most sought-after ingredient amongst the condensed fumes in acetic acid, used as a fixative in dyeing cloth. Today, wood vinegar is promoted across the Far East as an organic and cheap pesticide and fertiliser.

I wanted to see if I could add to the chemical by-product menu I was developing to aid in my physical break down of wood. All in the exploration of the wonders of wood.

Frank, my little workshop helper, was back to help with the first burn. (If you spy any safety concerns, please ignore) ;)

A donated Transit van exhaust pipe was the perfect cooling chimney. It got incredibly hot, another source of energy perhaps?!

Only a small sample of the wood vinegar and wood tar collected. The yield was impressive considering the small amount of wood in the burner.

What a let down, it turned out to be a bit of a fail. My eager need to shut the burner down led to a drum full of chared wood. At least it was dry.

We decided to have a BBQ, regardless. Everything was looking very hopeful, until the burgers went on. Sod's law it would die!

Everything was looking very hopeful, until the burgers went on. Sod's law it would die!