In my last post I finished off by mentioning my increasingly love for my chainsaw. Yes it's loud and powerful. Yes I get to cut down trees - hugely satisfying. But essentually the chainsaw is a brilliant tool. While I was making my shaving horse I got a little impatient chipping away carving the seat, so I thought "Blow it, where's my chainsaw". Finding that with gentle encouragement and careful blade direction the chainsaw can make light work of carving, cutting, boring etc. Could this transfer into furniture making? Could my chainsaw be a portable mortising machine?

In my last post I finished off by mentioning my increasingly love for my chainsaw. Yes it's loud and powerful. Yes I get to cut down trees - hugely satisfying. But essentually the chainsaw is a brilliant tool. While I was making my shaving horse I got a little impatient chipping away carving the seat, so I thought "Blow it, where's my chainsaw". Finding that with gentle encouragement and careful blade direction the chainsaw can make light work of carving, cutting, boring etc. Could this transfer into furniture making? Could my chainsaw be a portable mortising machine?

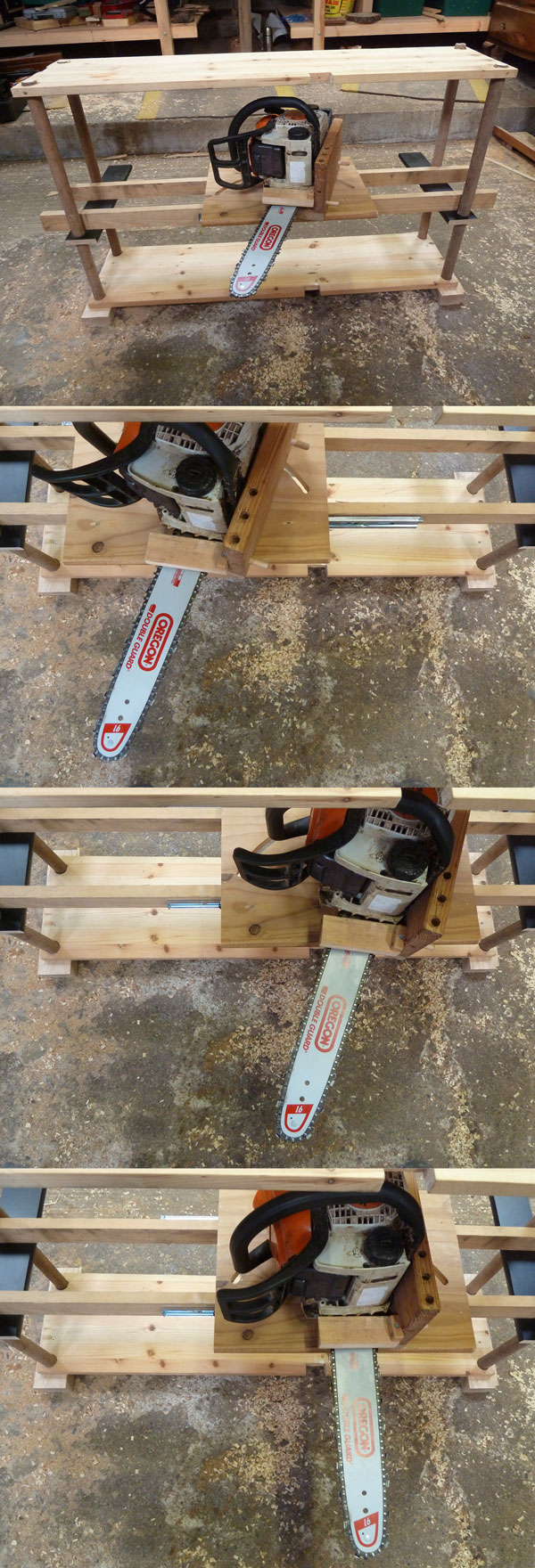

Again, using the Crack Willow was not the ideal timber, but I wanted to quickly test out the ease of boring out a mortise tenon joint. I was surprised, it wasn't ideal doing it freehand, but perhaps a jig could aid in accurate cuts.

My friend Paul, a greenwood worker and forester, helped me sketch up this 3D model to play with directions, pivots and heights that would be useful as a portable chainsaw CNC. Why was I so intent on using my chainsaw, apart from it being a fast and efficient machine?

Why was I so intent on using my chainsaw, apart from it being a fast and efficient machine?

At this point I had researched my material and the role it plays in the environment from the minute molecular level, the small scale craft traditions, all the way up to the industrial forestry management of softwoods. At each point there was always a cycle back to starting point - the woodland eco-system. No matter how big or small these cycles are, they could produce a number of by-products workable into my process. Chemicals, fuel, raw material, adhesives.. the list goes on.

By Charcoaling I was experimenting with the pyrolosis process - decomposing wood by heating without oxygen. This process gives off all sorts of gases, inparticular Carbon Monoxide, Ethanol and Methanol, all extremely flammable. YouTube is full of fun, crazy people using the gases in systems to power electrical generators, lawn mowers or even running cars around Europe! The best example I found, and the most fascinating fella doing amazing low tech things in the name of off grid eco living, in Texas - AllEnergies

In the quest for an on-site holistic system for manufacturing, generating my own power from wood felt like a momentus step in the right direction. I had discovered a simple moulding process for cooked chainsaw shavings, but I just wasn't satisfied - This project has researched into so any aspects of wood, as a varied resource. My imagination got the better of me, I wanted to run an electric chainsaw on wood! What a perfect loop that would be.

Cut down a tree. The trunk is planked, the shavings collected. The brash and branches are seasoned for firewood to boil the fresh shavings to mould. The heat could also be used to generate woodgas. The woodgas can be conbusted in a generator which in turn charges a battery for the chainsaw... etc etc. Had I more time during this project, I would have loved to see this happen.